Reinforced polymer materials are increasingly being used for structural applications because they allow manufacturers to replace traditional metal components with lighter-weight plastics. Long fiber composites, in particular, are well-suited for replacing metal, offering exceptional strength-to-weight ratio and the ease of injection molding, which can expand design options and streamline processing steps.

However, transitioning from metal to plastic requires thorough technical analysis and preparation. This is where enhanced virtual simulation capabilities can help, providing added value, driving innovation, supporting differentiation, and boosting confidence in structural polymer designs.

Advanced computer-aided engineering (CAE) software, when complemented by in-depth design and material knowledge, facilitates precise prediction of the behavior of fiber-reinforced polymer materials. The resulting virtual and technical insight allows part designers to:

- optimize and customize components

- create rapid part design iterations

- select appropriate materials

- mitigate risk

- validate and improve performance

- reduce costs early in development

- increase speed to market

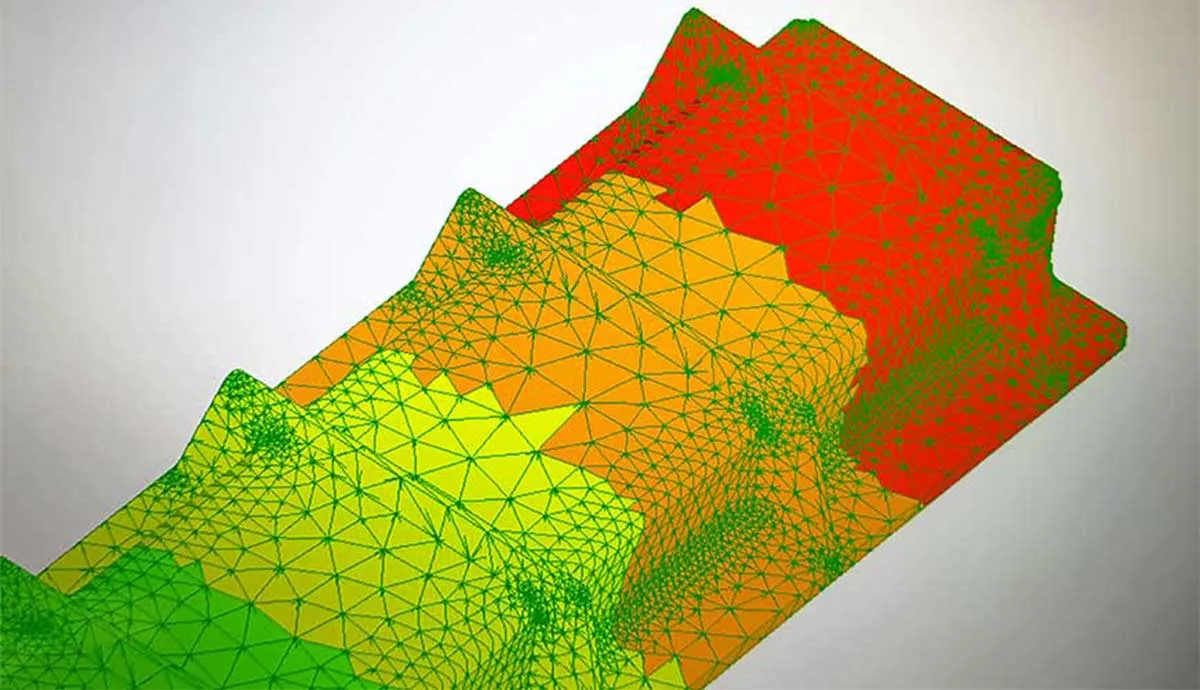

Predictive simulation technology uses conventional (isotropic) and advanced (anisotropic) modeling data from material characterizations, mold filling analysis, and finite element analysis (FEA) to more accurately forecast performance and potential failure points. By factoring in static and dynamic data, the CAE simulations can identify where an injection molded plastic part may crack or break when exposed to real-world conditions such as physical loading force, sudden impact (crash simulation), or environmental factors like temperature and humidity.

Advanced modeling also assists manufacturers and molders to:

- better identify and address potential deficiencies

- assess performance before investing in tooling or physical testing

- understand component behavior within a broader automotive system

For more technical details on the structural performance of reinforced polymers using CAE, automotive design engineers may access material data and models for Avient’s fiber-reinforced solutions using Hexagon’s Digimat-MX Tool. To discuss how advanced modeling may enhance your application, contact an expert at Avient today!